Reinstating Well Production after Valve Failure

Challenge

One of Europe’s leading independent oil and gas operators approached KCI with a problem.

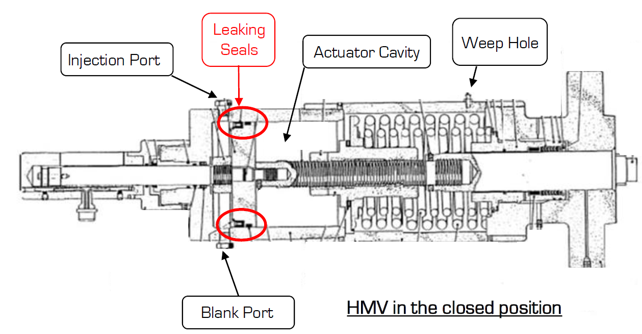

After routine maintenance on one of its wells, an actuated hydraulic master valve failed. With the valve stuck in the closed position due to an oil leak, gas could no longer flow, and the well was shut in.

Typically, the Operator would deploy its wireline crew and slant well intervention system to repair the valve. However, repair via these means was not an option with the well's crane being downrated.

Looking to reinstate £30,000 worth of lost daily production, the team sought a solution that would restore well integrity and allow the well to restart production as quickly and safely as possible.

Solution

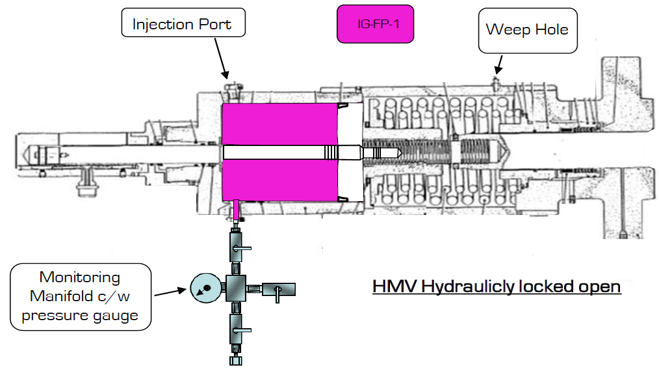

After looking into other options which did not meet requirements, the company opted for the novel solution of locking open the actuator hydraulically and injecting KCI’s IG-FP Sealant.

Providing oil and gas well integrity teams with an alternative to pressure-activated sealants, IG-FP is formulated to isolate hydraulic control line leaks in DHSV Control Line compression fittings where there is a hydraulic fluid leak.

Pumping into the control line at surface, IG-FP moves down to the leak path, creates a block to begin raising system pressure and is then forced through the leak path to fill the gaps around the compression fitting.

The sealant doesn't cure and remains suspended with no pressure. The KCI team engineers the operating volume upfront to ensure the leak path is covered and the valve remains open.

Result

The well was successfully restored, resulting in the production of approximately 2 million standard cubic feet (scf) of gas per day from a previously shut-in well.

IG-FP also allowed the client to retain the functionality of the well’s valve position monitoring system so that their control room could easily see the status of the valve.

The client now has a proven solution should future well shut-ins arise, and they are also looking into using the sealant for other well-sealing challenges.

Are you currently encountering any of these issues?

Get in touch today to find out how our leak sealing technology can help to safely and successfully reinstate valuable production in your wells.